525 kV XLPE DC Cable Systems – a key contributor in the green transformation

May 15, 2020

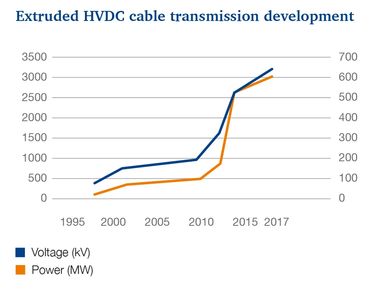

In May 2020, NKT won the first commercial order for a 525 kV extruded HVDC cable system with XLPE insulation for the 2 GW project SuedOstLink in Germany. The 525 kV cable system is a key element in developing a DC grid that can utilize renewable energy generation more efficiently.

- Press Releases & Events

- 525 kV XLPE DC Cable Systems – a key contributor in the green transformation

Loading...