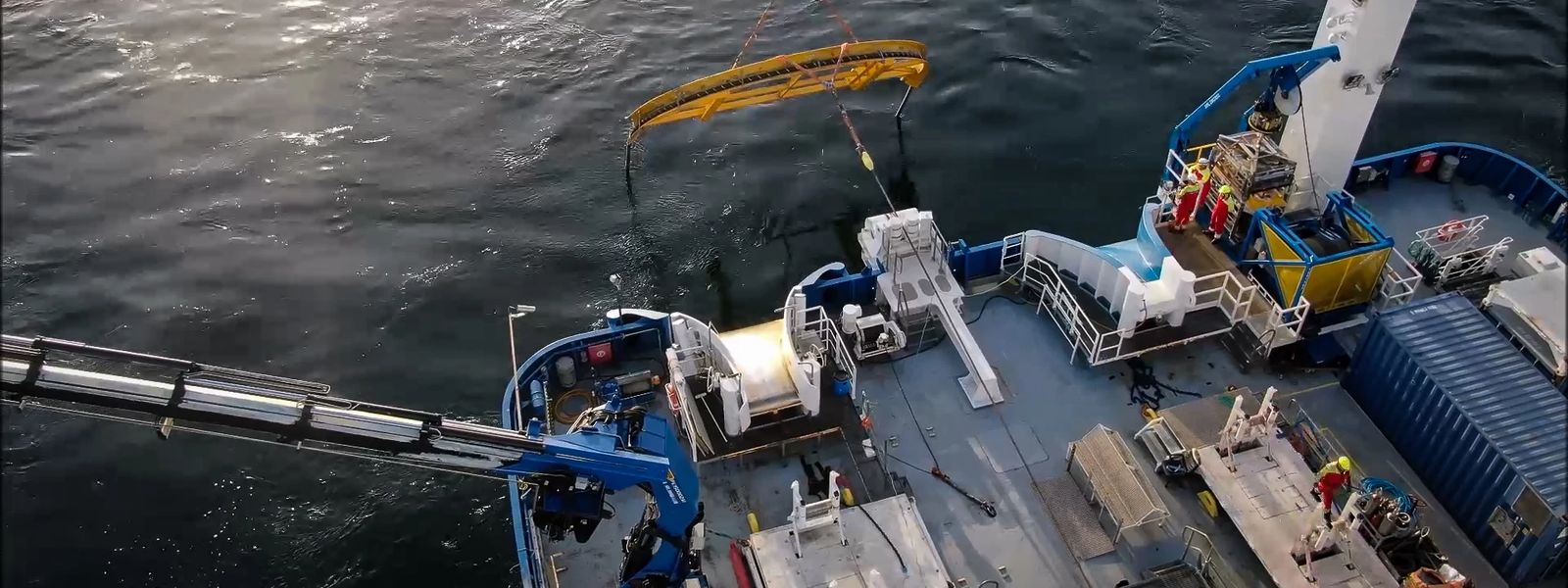

Baltic Cable Repair

Efficient repair of a submarine cable system between Sweden and Germany in just 29 days.

- References

- Baltic Cable Repair

Key facts

The Scope

A section of the Baltic Cable had been damaged and needed to be put back into operation quickly

We restored the power cable system in just 29 days

Time and accuracy are crucial for the success of power cable service operations and, here, we clearly demonstrated that we are quick and efficient when mobilizing our equipment and skilled repair team.

— Axel Barnekow Widmark, EVP, Head of Service at NKT

Loading...