Best-in-class technology

Our innovative products save time during installation and make for a more reliable network

- Products & Solutions

- Cable Accessories

- Technology & Engineering

Cold-applied technology

For a safe, fast, and easy installation

Cable accessories that are cold-applied come in two different forms. Firstly, they may use a sleeve of silicone insulation that is simply pushed into place. Alternatively, they may be applied with their silicon sleeve stretched onto a spiral device. In both cases, the process is incredibly quick compared with the outdated heat shrink process.

When heat had to be applied by a jointer during installation, there was always the possibility of imperfect results due to the unpredictability of environmental factors and the possibility of human error. By contrast, cold-applied, high-quality silicone insulation sleeves go into place easily and consistently form an even seal. This saves time and money not only during installation but also in the long term as maintenance is reduced. Another important advantage of cold-applied technology is the reduced risk to the installer. The use of a direct flame during the old heat shrink process – often in the presence of combustible gases – was inherently risky. Cold application eradicates this danger and removes the need for hot work permits.

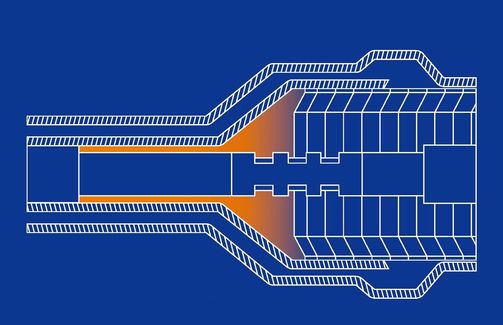

Geometric field control elements

Reducing the risk of cable failures

Cable failure caused by high frequencies is an ever-present danger in power transmission. Geometric field control elements built into many of our accessories – including all high-voltage accessories – help prevent this from occurring.

High frequencies are a danger because they cause heat production. This may become so intense that it can even ignite certain cable materials, such as fabrics. If the cable employs the refractive approach to field control, this may actually exacerbate the problem, since it encourages harmonics – precisely the kind of dangerous high frequency that generates high levels of heat.

There is a particular risk of problematic high frequencies occurring in renewable energy applications such as wind turbine connections, since they are particularly exposed to voltages with high and strongly fluctuating frequencies. By using geometric field control elements in our products, we are therefore making an important contribution to the viability of renewable energy networks.

See how the geometric field control works

Loading...